...

| Div | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| |||||||||||||||||

|

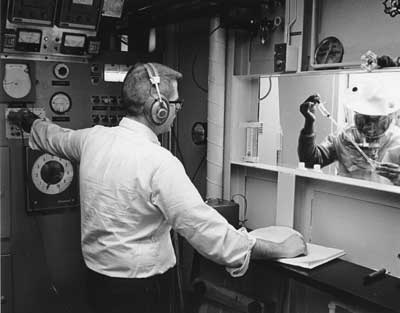

Fermenter Room

The fermenter room in Building 3 had facilities for growing and harvesting a large quantity of bacterial or yeast cells from which various enzymes could be extracted. Earl's research on metabolic regulation was particularly dependent upon the mass-production of glutamine synthetase in this room. The cell-growing procedure starts with a small culture of cells. This culture is scaled up to 10 or 20 liters in flasks, and then is introduced into the large fermenter which has a maximum volume of 500 liters. Typically, a volume of 350 liters is used for cells growing in an aerobic condition. The cells in the fermenter are then moved to a continuous flow centrifuge. As the centrifuge bowl spins at high speed, the cells are collected on the bowl's inside. The supernatant liquid overlying centrifuged cells flows out of the top and goes to a holding tank. This liquid is discarded after being chemically treated. The cells are scraped off, frozen in liquid nitrogen, and stored for enzyme purification. The frozen cells are suspended in a buffer solution and passed through a homogenizer, which uses high pressure to break the cells open and release the proteins. Finally, the enzyme is purified from cell-free extracts, according to various precipitation protocols. The 500-liter fermenter, installed around 1986, had an automatically-controlled valve system for sterilization, temperature control, agitation, and gas or air sparging . The fermenter prior to this model had been manually operated with about fifty different valves to open and close at various times. Earl and his assistants usually grew two fermenter-loads of E. coli a week. They then harvested 1200-1500 grams of cells, from which one gram of glutamine synthetase was purified. Now, the development of genetic engineering makes a large-scale fermenter almost obsolete. Only about 10 liters of the genetically modified organism that specifically overproduces glutamine synthetase are needed to harvest 30-50 grams of cells from which one gram of pure enzyme is obtained.

...