...

- Lewis Lipkin: optical microscopy of serial brain sections and macrophage motility measurements with asbestos

- Peter Lemkin: bone marrow smear analysis, 2D gel electrophoresis

- Bruce Shapiro: RNA secondary structure of electron micrograph

- Carl Merril: NIMH/NIH - 2-dimensional (2D) gel electrophoresis, E.coli mutants and macrophages with asbestos

- Jacob Maizel: NICHD/NIH, with Bruce Shapiro - RNA electron microscopy of secondary structure

- Eric Lester: NCI, U. Chicago, and oncology practice - 2D gel electrophoresis on human leukemia

- Steve Aley and Russell Howard: NIAID/NIH - 2D gel electrophoresis of Plasmodium knowlesi clones

- Peter Wirth and Snorri Thorgeirsson: NCI/NIH - 2D gel electrophoresis on liver cell lines

- Peter Sonderegger: NICHD/NIH and U. Zurich - 2D gel electrophoresis of axonal proteins of sensory and motor neurons

| Div | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ||||||||||

|

| Div | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ||||||||||

|

...

| Anchor | ||||

|---|---|---|---|---|

|

| Div | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ||||||||||

|

Anchor RTPP-Quantimet-PDP8e-blockDiagram RTPP-Quantimet-PDP8e-blockDiagram

| Div | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ||||||||||

|

...

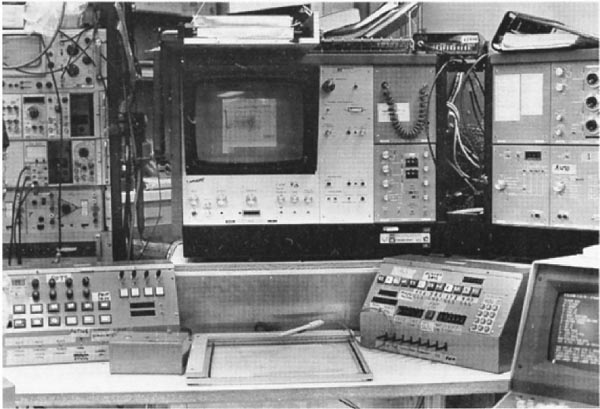

Anchor ControlDesk ControlDesk

| Div | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ||||||||||

|

...

Anchor PhotoRTPPandConsole PhotoRTPPandConsole

...

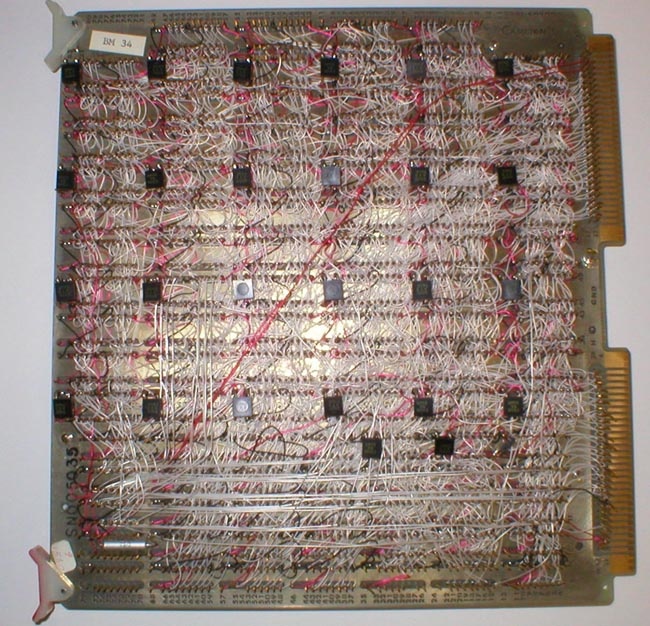

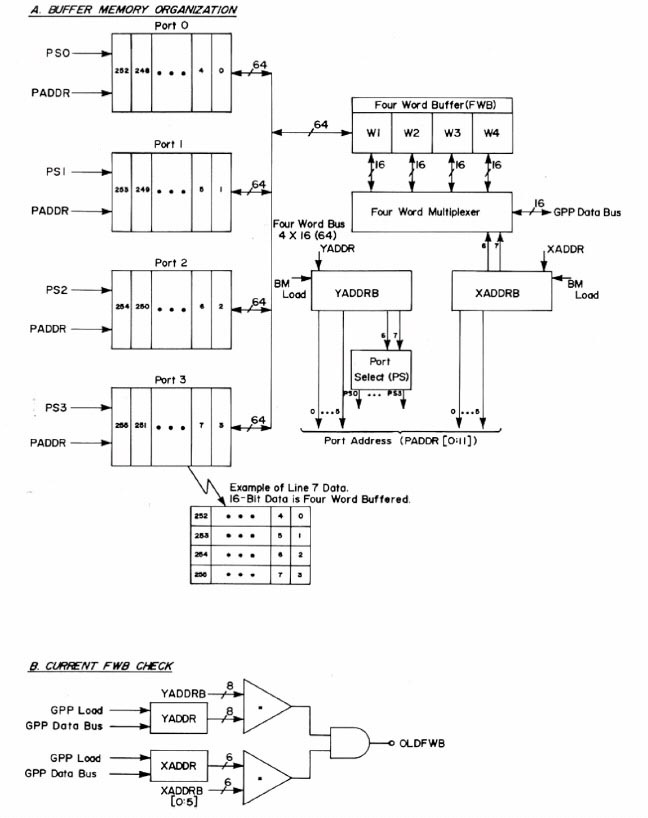

During this time, we had the conviction, led by Lew Lipkin and George Carman, that anything that we wanted to be do in software could be done by a series of sequential gates. These could be proved Boolean algebraically correct using Karnaugh Maps, hardware finite state machines, and related techniques. George had just taken a microprogramming design course as part of his masters degree in computer hardware architecture and the design of buffer memories and the General Picture Processor (GPP) were perfect test beds in which to try out these new design principles which were relatively new for projects like this. Some of the design diagrams are shown in Figures 11 through 14 (from the Carman [4] paper). Figure 15 shows some examples of GPP microprogrammed instructions for manipulating the buffer memory data. The design was further described in some of the technical reports [TR-7, TR-7a, TR-16, TR-21, TR-21b, TR-22] listed at the end of this history. Because we were prototyping the system, the card was constructed using wire wrapping rather than multilayer printed circuit boards. A commercial version would have used printed circuit boards, but would only have been economically feasible if many copies of the RTPP were produced. Using complex multi-level printed circuit boards is generally too expensive for a research lab.

| Anchor | ||||

|---|---|---|---|---|

|

| Div | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ||||||||||

|

...

Anchor TMS4030chip TMS4030chip

| Div | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ||||||||||

|

| Div | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ||||||||||

|

Anchor Fig-RTPP-BufferMemory-control-logic Fig-RTPP-BufferMemory-control-logic

| Div | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ||||||||||

|

| Anchor | ||||

|---|---|---|---|---|

|

| Div | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ||||||||||

|

| Div | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ||||||||||

|

...